摘要:本应用笔记介绍怎样使用MAX1233/MAX1234

触摸屏控制器的功能。所提供的简化控制台菜单系统支持对MAX1233/MAX1234器件

寄存器的底层直接访问。每一寄存器在32个SPI™

时钟周期内完成读写操作。软件对每一寄存器使用简短的助记名。使用MAX1234评估板(EV Kit)和MINIQUSB+命令模块时,软件支持最大底层控制。在随附的zip文件中,提供所有源代码。

MAX1233的工作方式和MAX1234一致,只是MAX1233采用3.3V供电,而不是5.0V。MAX1234评估板上的跳接器JU1使MAX1234工作在3.3V,以仿真MAX1233。

注意:符号"/" (例如,/CS)表示CS、PENIRQ、KEYIRQ和BUSY引脚为低电平有效。

内容目录

MAX1233/MAX1234触摸屏控制器入门

1.1) 需要的硬件

1.2) MINIQUSB+固件更新说明

1.3) 设置

1.4) 步骤

1.5) 解释SPI data in实例格式

2)vwin I/O实例

2.1) 控制DAC输出电压

2.2) 选择ADC基准电源模式

2.3) 测量外部电压输入AUX1和AUX2

2.4) 将AUX1和AUX2转换结果译为物理值

2.5) 测量外部电压输入BAT1和BAT2

2.6) 将BAT1和BAT2转换结果译为物理值

2.7) 测量内部温度TEMP1和TEMP2

2.8) 将TEMP1转换结果译为物理值

2.9) 将TEMP1和TEMP2转换结果译为物理值

2.10) 测量外部电压输入AUX1、AUX2、BAT1、BAT2和温度

3) 触摸屏实例

3.1) 低成本商用触摸屏

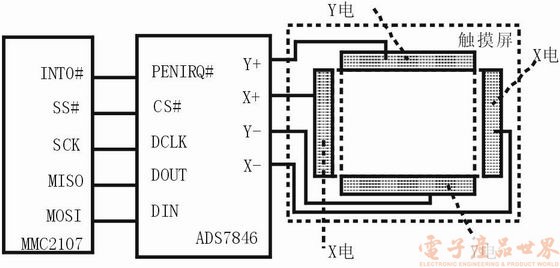

3.2) 连接触摸屏和评估板

3.3) 验证触摸屏的连接

3.4)检测触摸屏操作:根据需要扫描

3.5) 检测触摸屏操作:自动扫描

4) 键盘和通用输入/输出引脚

4.1) 配置键盘和GPIO引脚

4.2) 读写GPIO引脚

4.3) 检测按键:自动扫描

4.4) 从键盘中屏蔽单个按键

4.5) 从键盘中屏蔽一列

5) 管理功耗

6) 菜单系统

6.1) 寄存器读/写命令

6.2) 中断和状态引脚命令

6.3) 加入到更新后的MINIQUSB+固件中的命令

7) 结论

除了提高SPI接口的/CS时序之外,固件更新还包括中断驱动脉冲累加器,在MAX1233/MAX1234配置为自动扫描模式时,支持验证/PENIRQ和/KEYIRQ是否发送其自清除中断脉冲。/PENIRQ的持续时间取决于所配置的ADC转换率,/KEYIRQ的持续时间取决于所配置的开关反弹时间。

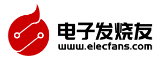

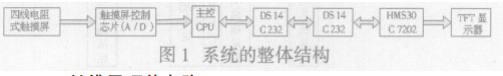

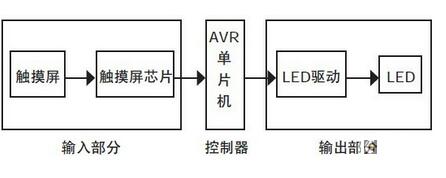

根据图1来组装硬件。

图1. 硬件配置(在后面章节中连接触摸屏)。

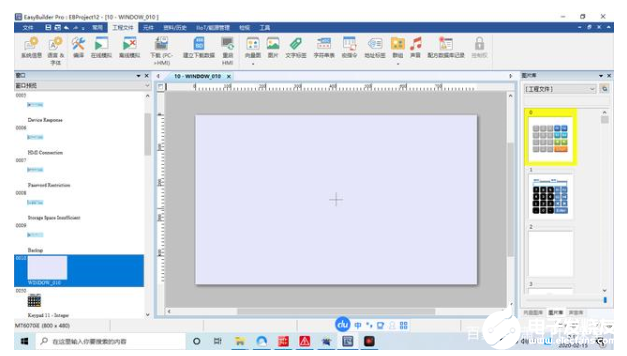

图2. 系统图片,使用一个3M内部连接器来连接MINIQUSB+和MAX1234评估板。

* DEMO1234 Command命令列出了输入到DEMO1234.exe程序中的命令。

** Verification列出了可以进行的物理测试,验证所执行的命令。

寄存器写操作是0000 0000 a7-a0 d15-d0格式的32位SPI传送过程。

寄存器读操作是1000 0000 a7-a0 0000 0000格式的32位SPI传送过程,在最后16位,接收到的数据从DOUT同步输入。

对于AVDD = 3.3V ±5%,DACOUT满量程范围在2.65V和3.27V之间,通常为2.96V。

对于AVDD = 5.0V ±5%,DACOUT满量程范围在4.02V和4.97V之间,通常为4.48V。

表3. DAC输出命令

对于第一次诊断,保持上电模式(ADC3210 = 0000,RES10 = 01)支持使用手持式DVM对基准电压进行外部验证。

ADC扫描选择位设置为0000,写入ADC控制寄存器(0x40),来设置ADC基准电源模式。RES1/RES0位选择基准电源模式,基准控制位RFV选择内部1.0V或者2.5V基准(请参考MAX1233/MAX1234数据资料的表13)。

ADC控制字:x x 0 0 0 0 RES1 RES0 x x x x x x x RFV

表4. 内部基准命令

表5. 外部基准命令

表10. 触摸屏物理连接验证命令序列

表11. 纠正触摸屏连接问题

表12. 触摸屏检测命令序列:根据需要扫描

表13. 触摸屏检测命令序列:自动扫描

表14. 键盘和GPIO配置实例

表15. GPIO实例

表16. 按键命令序列:自动扫描

表17. 按键命令序列:屏蔽单个按键

表18. 按键命令序列:屏蔽键盘的一列

CmodComm测试程序主菜单—在连接前

A) adjust timing parameters

L) CmodLog... functions

C) connect

D) Debug Messages

X) exit

对C (连接)命令的响应

C

Hardware supports optimized native SMBus commands.

Board connected.

Got board banner: Maxim MINIQUSB V01.05.41 >

Firmware version is OK.

(configured for SPI auto-CS 4-byte mode) (SCLK=2MHz) ...

主菜单—连接后有效

T) Test the device

8) CmodP8Bus... functions

A) adjust timing parameters

L) CmodLog... functions

P) CmodPin... functions

S) CmodSpi... functions

M) CmodSMBus... functions

$) CmodCommStringWrite list of hex codes

R) CmodBoardReset

D) Disconnect

测试菜单命令—连接后有效

R) Read register

W) Write register

M0) measure no measurement; configure reference

M1) measure X,Y

M2) measure X,Y,Z1,Z2

M3) measure X

M4) measure Y

M5) measure Z1,Z2

M6) measure BAT1/4

M7) measure BAT2/4

M8) measure AUX1

M9) measure AUX2

MA) measure TEMP1

MB) measure BAT1/4,BAT2/4,AUX1,AUX2,TEMP1,TEMP2

MC) measure TEMP1,TEMP2

MD) no measurement; drive Y+,Y-

ME) no measurement; drive X+,X-

MF) no measurement; drive Y+,X-

.) Exit this menu

表21. 写入寄存器助记符

表22. 触摸屏测量命令序列

表25. 更新后MINIQUSB+固件01.05.41中的中断脉冲累加器命令

MAX1233的工作方式和

注意:符号"/" (例如,/CS)表示CS、PENIRQ、KEYIRQ和BUSY引脚为低电平有效。

内容目录

MAX1233/MAX1234触摸屏控制器入门

1.1) 需要的硬件

1.2) MINIQUSB+固件更新说明

1.3) 设置

1.4) 步骤

1.5) 解释SPI data in实例格式

2)vwin I/O实例

2.1) 控制DAC输出电压

2.2) 选择ADC基准电源模式

2.3) 测量外部电压输入AUX1和AUX2

2.4) 将AUX1和AUX2转换结果译为物理值

2.5) 测量外部电压输入BAT1和BAT2

2.6) 将BAT1和BAT2转换结果译为物理值

2.7) 测量内部温度TEMP1和TEMP2

2.8) 将TEMP1转换结果译为物理值

2.9) 将TEMP1和TEMP2转换结果译为物理值

2.10) 测量外部电压输入AUX1、AUX2、BAT1、BAT2和温度

3) 触摸屏实例

3.1) 低成本商用触摸屏

3.2) 连接触摸屏和评估板

3.3) 验证触摸屏的连接

3.4)检测触摸屏操作:根据需要扫描

3.5) 检测触摸屏操作:自动扫描

4) 键盘和通用输入/输出引脚

4.1) 配置键盘和GPIO引脚

4.2) 读写GPIO引脚

4.3) 检测按键:自动扫描

4.4) 从键盘中屏蔽单个按键

4.5) 从键盘中屏蔽一列

5) 管理功耗

6) 菜单系统

6.1) 寄存器读/写命令

6.2) 中断和状态引脚命令

6.3) 加入到更新后的MINIQUSB+固件中的命令

7) 结论

1.1) 需要的硬件

- MaximMAX1234评估板 (MAX1234EVKIT)

- Maxim MINIQUSB+ (包括USB A-B电缆和MINIQUSB-X+扩展板)

- Windows® 2000/XP PC,支持USB。

- 四线阻性触摸屏(例如,PDA数字转换器/玻璃屏等)

- 可选:测量DAC输出电压的DMM

- 可选:驱动AUX和BAT输入的电压源

- 可选:示波器,用于观察/PENIRQ和/KEYIRQ引脚上的自动扫描中断脉冲。

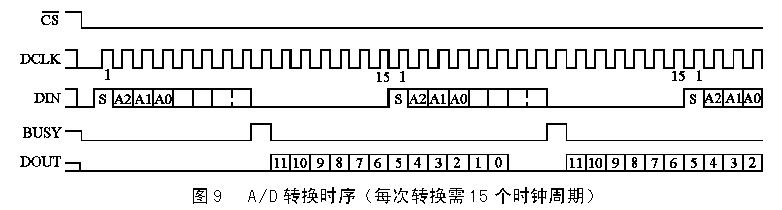

1.2) MINIQUSB+固件更新说明

MAX1233/MAX1234要求/CS引脚在第一次转换结束之前,解除高电平置位;否则,ADC将无法存储转换结果。在使用本应用笔记之前,必须更新标准MINIQUSB+模块固件,使SPI接口/CS引脚在第32个SCLK 1.4µs内解除置位。在2MHz时,32位自动/CS受控模式将/CS保持低电平21.70µs。只需要对MAXQ2000微控制器非易失闪存MINIQUSB+固件更新一次。这一新固件和标准01.05.39基本固件后向兼容。除了提高SPI接口的/CS时序之外,固件更新还包括中断驱动脉冲累加器,在MAX1233/MAX1234配置为自动扫描模式时,支持验证/PENIRQ和/KEYIRQ是否发送其自清除中断脉冲。/PENIRQ的持续时间取决于所配置的ADC转换率,/KEYIRQ的持续时间取决于所配置的开关反弹时间。

1.3) 设置

下载并解压缩应用笔记文件 (ZIP, 2.4MB)。根据图1来组装硬件。

- 按照表1连接MAX1234评估板连接器J1和MINIQUSB-X+扩展电路板(包含在MINIQUSB+中)。可以采用3M®内部连接器922576-40来替代连接MAX1234评估板的焊线,将其插入到J1中,以提供方便的连接点。不要连接终端模块TB1。

表1. MAX1234评估板和MINIQUSB+电路板之间的连接设置

* 注释:必须通过连接器J1来驱动MAX1234评估板数字输入,不能直接将其驱动至U1周围的测试点。必须采用板上MAX1841电平转换器来驱动MAX1234评估板数字信号。MAX1234 Signal MAX1234 EV Kit MINIQUSB-X+ MINIQUSB Signal GND J1-1 H2-8 GND VCC J1-7 H2-1 3.3V supply from MINIQUSB+ BUSY-Bar J1-27 H2-7 GPIO-K7 (MAXQ2000-INT2) PENIRQ-Bar J1-29 H1-3 GPIO-K6 (MAXQ2000-INT1) KEYIRQ-Bar J1-31 H1-8 GPIO-K5 (MAXQ2000-INT0) DOUT J1-35* H2-2 MISO (SPI master in, slave out) DIN J1-36* H2-5 MOSI (SPI master out, slave in) SCLK J1-37* H2-3 SCLK (SPI clock) CS-Bar J1-38 H2-4 CS-bar (SPI chip select) USB+5V J1-5 J4-7 USB+5V supply from PC - 将MINIQUSB+插入到扩展板的顶部。

- 连接MINIQUSB+和PC的USB端口。如果这是MINIQUSB+第一次和PC连接,将出现即插即用向导。指南窗口将提示器件驱动器(它包含在随附zip文件中)的安装位置。

- 启动固件更新批处理文件FWUPDATE.BAT来更新MINIQUSB+固件。

- 固件更新完成后,从PC的USB端口断开MINIQUSB+。

图1. 硬件配置(在后面章节中连接触摸屏)。

图2. 系统图片,使用一个3M内部连接器来连接MINIQUSB+和MAX1234评估板。

1.4) 步骤

- 将MAX1234评估板跳接器JU1设置到“MAX1234”位置。

- 将MINIQUSB+连接至PC的USB端口。确定DACOUT电压 = mid-scale (2.2V)。

- 启动DEMO1234.EXE程序。屏幕上将出现控制台。

- 在控制台中输入下面的命令序列。

DEMO1234 Command* |

Expected ProgramOutput | SPI data in |

Verification** |

C |

Board connected. Got board banner: Maxim MINIQUSB V01.05.41 > Firmware version is OK. (configured forSPI auto-CS 4-byte mode) (SCLK=2MHz) ... |

||

T W DD FF |

Write_Register(regAddr=0x000b wr_DAC_data , data=0x00ff {(no bits defined for this register)}) result = 1 |

0x000b 0x00ff | DACOUT = full-scale (4.5V) |

T R DD |

Read_Register(regAddr=0x800b wr_DAC_data ) result = 1, buffer = 0x00ff = 255 {(no bits defined for this register)} |

0x800b 0x0000 | Data buffer = 0x00ff |

T W DD 80 |

Write_Register(regAddr=0x000b wr_DAC_data , data=0x0080 {(no bits defined for this register)}) result = 1 |

0x000b 0x0080 | DACOUT = mid-scale (2.2V) |

T R DD |

Read_Register(regAddr=0x800b wr_DAC_data ) result = 1, buffer = 0x0080 = 128 {(no bits defined for this register)} |

0x800b 0x0000 | data buffer = 0x0080 |

** Verification列出了可以进行的物理测试,验证所执行的命令。

1.5) SPI data in实例格式

SPI data in一列列出了驱动至MAX1233/MAX1234 DIN引脚的SPI数据,采用了十六进制格式,最高有效字节在前。例如,序列0x000b 0x00ff中的SPI数据表示同步输入到DIN的32位序列是0000 0000 0000 1011 0000 0000 1111 1111。第一位0用于寄存器写操作,1用于寄存器读操作。寄存器写操作是0000 0000 a7-a0 d15-d0格式的32位SPI传送过程。

寄存器读操作是1000 0000 a7-a0 0000 0000格式的32位SPI传送过程,在最后16位,接收到的数据从DOUT同步输入。

2) 模拟I/O实例

下面的例子介绍了怎样使用DEMO1234.EXE程序来控制DAC输出,配置基准电压,测量AUX1/AUX2/BAT1/BAT2电压输入,以及测量内部MAX1234温度。2.1) 控制DAC输出电压

由两个寄存器来控制DAC。写入DAC数据寄存器来设置输出电压。写入DAC控制寄存器来关断或者对DAC上电。默认上电状态是DAC加电,DAC输出位于量程中部。DAC满量程电压通常为AVDD的90% (最小85%,最大95%)。对于AVDD = 3.3V ±5%,DACOUT满量程范围在2.65V和3.27V之间,通常为2.96V。

对于AVDD = 5.0V ±5%,DACOUT满量程范围在4.02V和4.97V之间,通常为4.48V。

表3. DAC输出命令

DEMO1234 Command |

Action | SPI data in |

MAX1233 (3.3V) | MAX1234 (5.0V) |

T W DD FF |

DACOUT = full-scale | 0x000b 0x00ff |

DACOUT = 2.96V | DACOUT = 4.48V |

T W DD 00 |

DACOUT = 0V | 0x000b 0x0000 |

DACOUT = 0.0V | DACOUT = 0.0V |

T W DD 80 |

DACOUT = mid-scale | 0x000b 0x0080 |

DACOUT = 1.485V | DACOUT = 2.25V |

T WDC8000 |

Disable DAC | 0x0042 0x8000 |

DACOUT = 0.0V | DACOUT = 0.0V |

T W DC 0 |

Enable DAC | 0x0042 0x0000 |

DACOUT = 1.485V | DACOUT = 2.25V |

2.2) 选择ADC基准电源模式

ADC需要一个基准电压。对于典型的嵌入式系统工作,默认设置是fine。在自动上电模式(ADC3210 = 0000,RES10 = 00)下,MAX1233/MAX1234提供自己的内部基准电压。在每次测量之前,内部基准自动上电,测量完成后关断。对于第一次诊断,保持上电模式(ADC3210 = 0000,RES10 = 01)支持使用手持式DVM对基准电压进行外部验证。

ADC扫描选择位设置为0000,写入ADC控制寄存器(0x40),来设置ADC基准电源模式。RES1/RES0位选择基准电源模式,基准控制位RFV选择内部1.0V或者2.5V基准(请参考MAX1233/MAX1234数据资料的表13)。

ADC控制字:x x 0 0 0 0 RES1 RES0 x x x x x x x RFV

表4. 内部基准命令

DEMO1234 Command |

Action | SPI data in |

Verification |

T W AC 0100 |

Internal 1V reference always powered; write ADC control word with ADC3210 = 0000, RES10 = 01, RFV = 0 |

0x0040 0x0100 |

Voltage atpin 12 REF is between 0.98V and 1.02V |

T W AC 0101 |

Internal 2.5V reference always powered; write ADC control word with ADC3210 = 0000, RES10 = 01, RFV = 1 |

0x0040 0x0101 |

Voltage at pin 12 REF is between 2.47V and 2.53V |

T W AC 0001 |

Internal 2.5V reference powered when needed; write ADC control word with ADC3210 = 0000, RES10 = 00, RFV = 1 |

0x0040 0x0001 |

Voltage at pin 12 REF will be powered only briefly as necessary |

表5. 外部基准命令

DEMO1234 Command |

Action | SPI data in |

T W AC 0300 |

External reference must be provided; ADC_control_wr_demand_scan:(write)demand scan ADC_control_AD0000:configure reference ADC_control_RES11:external reference |

0x0040 0x0300 |

2.3) 测量外部电压输入AUX1和AUX2

表6. ADC测量命令序列DEMO1234 Command |

Action (Triggered by A/D3210 Bits) | SPI data in |

T M8 |

Measure AUX1 with 12-bit resolution and 3.5µs conversion rate | 0x0040 0x2301 0x8007 0x0000 |

T W AC 2301 |

Trigger ADC scan of AUX1; ADC control word 0x2301 means: ADC_control_wr_demand_scan ADC_control_AD1000 /* measure AUX1 */ ADC_control_RES11 /* 12-bit resolution */ ADC_control_AVG00 /* no averaging */ ADC_control_CNR00 /* conversion rate 3.5µs */ ADC_control_RFV /* RFV=1:VREF=2.5V */ |

0x0040 0x2301 |

T R A1 |

Read AUX1 result AUX1_code | 0x8007 0x0000 |

T M9 |

Measure AUX2 with 12-bit resolution and 3.5µs conversion rate | 0x0040 0x2701 0x8008 0x0000 |

2.4) 将AUX1和AUX2转换结果译为物理值

下面的C/C++伪代码片断总结了DEMO1234程序是怎样解释AUX1和AUX2转换结果的。/* ADC control resolution value selects num_codes 4096 (12-bit), 1024 (10-bit), or 256 (8-bit) */ int num_codes = 4096; /* ADC_control_RES11: 12-bit resolution */ /* Voltage that corresponds to the full-scale ADC code; may be internal 1V or 2.5V ref, or ext ref. */ double ADC_fullscale_voltage = 2.5; /* ADC_control_RFV=1: VREF=2.5V. RFV=0: VREF=1.0V. */ /* AUX1_code is the 16-bit result read by SPI command 0x8007 */ double AUX1_Voltage = (AUX1_code * ADC_fullscale_voltage) / num_codes; /* AUX2_code is the 16-bit result read by SPI command 0x8008 */ double AUX2_Voltage = (AUX2_code * ADC_fullscale_voltage) / num_codes;

2.5) 测量外部电压输入BAT1和BAT2

表7. ADC测量命令序列DEMO1234 Command |

Action (Triggered by A/D3210 Bits) | SPI data in |

T M6 |

Measure BAT1 with 12-bit resolution and 3.5µs conversion rate | 0x0040 0x1b01 0x8005 0x0000 |

T W AC 1b01 |

Trigger ADC scan of BAT1; ADC control word 0x1b01 means: ADC_control_wr_demand_scan ADC_control_AD0110 /* measure BAT1 */ ADC_control_RES11 /* 12-bit resolution */ ADC_control_AVG00 /* no averaging */ ADC_control_CNR00 /* conversion rate 3.5µs */ ADC_control_RFV /* RFV=1: VREF=2.5V */ |

0x0040 0x1b01 |

T R B1 |

Read BAT1 result BAT1_code | 0x8005 0x0000 |

T W AC 1b21 |

Trigger ADC scan of BAT1; ADC control word 0x1b21 means: ADC_control_wr_demand_scan ADC_control_AD0110 /* measure BAT1 */ ADC_control_RES11 /* 12-bit resolution */ ADC_control_AVG00 /* no averaging */ ADC_control_CNR10 /* conversion rate 10µs */ ADC_control_RFV /* RFV=1: VREF=2.5V */ |

0x0040 0x1b21 |

T R B1 |

Read BAT1 result BAT1_code | 0x8005 0x0000 |

T M7 |

Measure BAT2 with 12-bit resolution and 3.5µs conversion rate | 0x0040 0x1f01 0x8006 0x0000 |

2.6) 将BAT1和BAT2转换结果译为物理值

下面的C/C++伪代码片断总结了DEMO1234程序是怎样解释BAT1和BAT2转换结果的。注意:通过一个4:1输入分配器来测量BAT1和BAT2。/* ADC control resolution value selects num_codes 4096 (12-bit), 1024 (10-bit), or 256 (8-bit) */ int num_codes = 4096; /* ADC_control_RES11: 12-bit resolution */ /* Voltage that corresponds to the full-scale ADC code; may be internal 1V or 2.5V ref, or ext ref. */ double ADC_fullscale_voltage = 2.5; /* ADC_control_RFV=1: VREF=2.5V. RFV=0: VREF=1.0V. */ /* Note: BAT1 and BAT2 measure through a 4:1 input divider. */ /* BAT1_code is the 16-bit result read by SPI command 0x8005 */ double BAT1_Voltage = 4 * (BAT1_code * ADC_fullscale_voltage) / num_codes; /* BAT2_code is the 16-bit result read by SPI command 0x8006 */ double BAT2_Voltage = 4 * (BAT2_code * ADC_fullscale_voltage) / num_codes;

2.7) 测量内部温度TEMP1和TEMP2

表8. ADC测量命令序列DEMO1234 Command |

Action (Triggered by A/D3210 Bits) | SPI data in |

T MA |

Measure TEMP1 with 12-bit resolution and 3.5µs conversion rate | 0x0040 0x2b01 0x8009 0x0000 |

T W AC 2b01 |

Trigger ADC scan of TEMP1; ADC control word 0x2b01 means: ADC_control_wr_demand_scan ADC_control_ AD1010 /* measure TEMP1 */ ADC_control_RES11 /* 12-bit resolution */ ADC_control_AVG00 /* no averaging */ ADC_control_CNR00 /* conversion rate 3.5µs */ ADC_control_RFV /* RFV=1: VREF=2.5V */ |

0x0040 0x2b01 |

T R T1 |

Read TEMP1 result TEMP1 _code | 0x8009 0x0000 |

T MC |

Measure TEMP1, TEMP2 with 12-bit resolution and 3.5µs conversion rate | 0x0040 0x3301 0x8009 0x0000 0x800a 0x0000 |

T W AC 3301 |

Trigger ADC scan of TEMP1 and TEMP2; ADC control word 0x3301 means: ADC_control_wr_demand_scan ADC_control_ AD1100 /* measure TEMP1,TEMP2 */ ADC_control_RES11 /* 12-bit resolution */ ADC_control_AVG00 /* no averaging */ ADC_control_CNR00 /* conversion rate 3.5µs */ ADC_control_RFV /* RFV=1: VREF=2.5V */ |

0x0040 0x3301 |

T R T1 |

Read TEMP1 result TEMP1 _code | 0x8009 0x0000 |

T R T2 |

Read TEMP2 result TEMP2 _code | 0x800a 0x0000 |

2.8) 将TEMP1转换结果译为物理值

下面的C/C++伪代码片断总结了DEMO1234程序是怎样解释TEMP1转换结果的。/* ADC control resolution value selects num_codes 4096 (12-bit), 1024 (10-bit), or 256 (8-bit) */ int num_codes = 4096; /* ADC_control_RES11: 12-bit resolution */ /* Voltage that corresponds to the full-scale ADC code; may be internal 1V or 2.5V ref, or ext ref. */ double ADC_fullscale_voltage = 2.5; /* ADC_control_RFV=1: VREF=2.5V. RFV=0: VREF=1.0V. */ /* TEMP1_code is the 16-bit result read by SPI command 0x8009 */ double TEMP1_Voltage = (TEMP1_code * ADC_fullscale_voltage) / num_codes; /* Calibration values */ const double Temp1V_Room = 0.590; // temp1 voltage at room temperature 25C const double Temp1K_Room = 298.15; // Room temperature Kelvins (298.15K=25C) const double Temp1V_Per_K = -0.002; // TempCo -2mV per degree C /* Convert to absolute temperature */ double Kelvin = (TEMP1_Voltage - Temp1V_Room) / Temp1V_Per_K + Temp1K_Room; /* Optional conversion to commonly used temperature units */ double Centigrade = Kelvin - 273.15; double Fahrenheit = (Centigrade * 9.0 / 5.0) + 32;

2.9) 将TEMP1和TEMP2转换结果译为物理值

下面的C/C++伪代码片断总结了DEMO1234程序是怎样解释TEMP1和TEMP2转换结果的。TEMP2只在和TEMP1对比时才有意义。/* ADC control resolution value selects num_codes 4096 (12-bit), 1024 (10-bit), or 256 (8-bit) */ int num_codes = 4096; /* ADC_control_RES11: 12-bit resolution */ /* Voltage that corresponds to the full-scale ADC code; may be internal 1V or 2.5V ref, or ext ref. */ double ADC_fullscale_voltage = 2.5; /* ADC_control_RFV=1: VREF=2.5V. RFV=0: VREF=1.0V. */ /* TEMP1_code is the 16-bit result read by SPI command 0x8009 */ double TEMP1_Voltage = (TEMP1_code * ADC_fullscale_voltage) / num_codes; /* TEMP2_code is the 16-bit result read by SPI command 0x800a */ double TEMP2_Voltage = (TEMP2_code * ADC_fullscale_voltage) / num_codes; /* Calibration values */ const double K_Per_Temp21_Delta_V = 2680.0; // nominal 2680 5/27/2002 /* Convert to absolute temperature */ double Kelvin = (TEMP2_Voltage - TEMP1_Voltage) * K_Per_Temp21_Delta_V; /* Optional conversion to commonly used temperature units */ double Centigrade = Kelvin - 273.15; double Fahrenheit = (Centigrade * 9.0 / 5.0) + 32;

2.10) 测量外部电压输入AUX1、AUX2、BAT1、BAT2和温度

表9. ADC测量命令序列DEMO1234 Command |

Action (Triggered by A/D3210 Bits) | SPI data in |

T MB |

Measure BAT1/4, BAT2/4, AUX1, AUX2, TEMP1, TEMP2 with 12-bit resolution and 3.5µs conversion rate | 0x0040 0x2f01 0x8005 0x0000 0x8006 0x0000 0x8007 0x0000 0x8008 0x0000 0x8009 0x0000 0x800a 0x0000 |

T W AC 2f01 |

Trigger ADC scan of BAT1-2, AUX1-2, TEMP1-2; ADC control word 0x2f01 means: ADC_control_wr_demand_scan ADC_control_ AD1011 /* measure AUX1 etc. */ ADC_control_RES11 /* 12-bit resolution */ ADC_control_AVG00 /* no averaging */ ADC_control_CNR00 /* conversion rate 3.5µs */ ADC_control_RFV /* RFV=1: VREF=2.5V */ |

0x0040 0x2f01 |

T R B1 |

Read BAT1 result BAT1 _code | 0x8005 0x0000 |

T R B2 |

Read BAT2 result BAT2_code | 0x8006 0x0000 |

T R A1 |

Read AUX1 result AUX1 _code | 0x8007 0x0000 |

T R A2 |

Read AUX2 result AUX2 _code | 0x8008 0x0000 |

T R T1 |

Read TEMP1 result TEMP1 _code | 0x8009 0x0000 |

T R T2 |

Read TEMP2 result TEMP2 _code | 0x800a 0x0000 |

3) 触摸屏实例

下面的例子解释了怎样使用DEMO1234.EXE程序来获得触摸屏数据。3.1) 低成本商用触摸屏

在互联网上搜索"PDA Digitizer/Glasstop",寻找合适的替代触摸屏。高清触摸屏玻璃的价格范围在50美元至10美元之间,价格取决于型号以及玻璃是否全部贴在显示屏上。3.2) 连接触摸屏和评估板

MAX1234评估板提供突出插头H5/H6来连接10mm柔性电缆或者长度更短的电缆。H6连接器的间距是0.5mm,比实际触摸屏柔性电缆间距更精细。把柔性电缆插入H6,上锁,选择位于四条柔性电缆中每一电缆中心位置的H5引脚。跳接器连接H5和标有U1的X+、Y+、X-以及Y-测试点。3.3) 检验触摸屏的连接

第一次连接触摸屏时,通过下面的步骤来验证X和Y连接是否正确。可以有几个触摸屏交叉连接,但大部分不会正常工作。在这些例子中,我们假设X- = left,X+ = right,Y- = top,Y+ = bottom。表10. 触摸屏物理连接验证命令序列

DEMO1234 Command |

Action | SPI data in |

Verification |

| Connect DVM to X+/GND | |||

T MD |

No measurement; drive Y+,Y- | 0x0040 0x3701 |

|

| Touch top left | X+ = approx. Y- | ||

| Touch top right | X+ = approx. Y- | ||

| Touch bottom left | X+ = approx. Y+ | ||

| Touch bottom right | X+ = approx. Y+ | ||

| Connect DVM to Y+/GND | |||

T ME |

No measurement; drive X+,X- | 0x0040 0x3b01 |

|

| Touch top left | Y+ = approx. X- | ||

| Touch top right | Y+ = approx. X+ | ||

| Touch bottom left | Y+ = approx. X- | ||

| Touch bottom right | Y+ = approx. X+ |

表11. 纠正触摸屏连接问题

| Symptom | Correction |

| Touch coordinates are mirrored top-to-bottom | Swap the Y+ and Y- connections |

| Touch coordinates are mirrored left-to-right | Swap the X+ and X- connections |

| Touch coordinates are rotated 180 degrees | Swap the X+ and X- connections, and swap the Y+ and Y- connections |

| Touch coordinates are mirrored diagonally | Swap the X+ and Y+ connections, and swap the X- and Y- connections |

| Touch coordinates do not seem to track, and the distortion is not asimple flip/rotate/mirror transformation | Swap the X+ and Y+ connections; if distortion persists, swap the X+ and Y- connections; if distortion still persists, disconnect touch screen and use DVM to verify X+ to X- resistance and Y+ to Y- resistance; verify with no touch X+ and X- are isolated from Y+ and Y- |

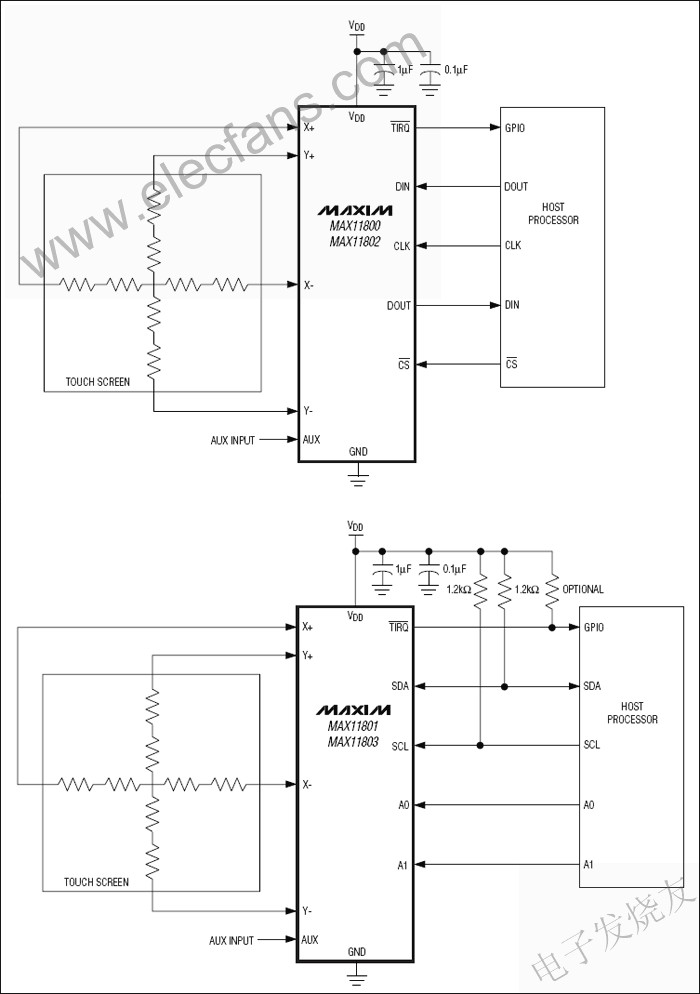

3.4) 检测触摸屏的操作:根据需要扫描

在配置MAX1234检测触摸屏操作,根据需要数字化接触屏的位置时,写入寄存器0x40 (ADC控制),其PENSTS=0,ADSTS=0 (请参考MAX1233/MAX1234数据资料的表6)。读取寄存器0x00 (X轴)后,检测到后续的触摸屏操作时,/PENIRQ信号锁存至低电平,在写入ADC控制寄存器测量X、Y轴之前,保持低电平。表12. 触摸屏检测命令序列:根据需要扫描

DEMO1234 Command |

Action | SPI data in |

Verification |

T W AC 0b01 |

Demand scan | 0x0040 0x0b01 |

|

T R AX |

Read conversion result register X | 0x8000 0x0000 |

|

P R 6 |

Read PENIRQ-bar pin status | PENIRQ = 1 | |

| Touch the touch screen | |||

P R 6 |

Read PENIRQ-bar pin status | PENIRQ = 0 | |

T M2 |

Measure X,Y,Z1,Z2 | 0x0040 0x0b01 0x8000 0x0000 0x8001 0x0000 0x8002 0x0000 0x8003 0x0000 |

|

P R 6 |

Read PENIRQ-bar pin status | PENIRQ = 1 | |

| Touch and hold the touch screen | |||

P R 6 |

Read PENIRQ-bar pin status | PENIRQ = 0 | |

T M2 |

Measure X,Y,Z1,Z2 | 0x0040 0x0b01 0x8000 0x0000 0x8001 0x0000 0x8002 0x0000 0x8003 0x0000 |

|

P R 6 |

Read PENIRQ-bar pin status | PENIRQ = 0 | |

T M2 |

Measure X,Y,Z1,Z2 | 0x0040 0x0b01 0x8000 0x0000 0x8001 0x0000 0x8002 0x0000 0x8003 0x0000 |

|

P R 6 |

Read PENIRQ-bar pin status | PENIRQ = 0 | |

| Release the touch screen | |||

P R 6 |

Read PENIRQ-bar pin status | PENIRQ = 0 | |

T M2 |

Measure X,Y,Z1,Z2 | 0x0040 0x0b01 0x8000 0x0000 0x8001 0x0000 0x8002 0x0000 0x8003 0x0000 |

|

P R 6 |

Read PENIRQ-bar pin status | PENIRQ = 1 |

3.5) 检测触摸屏操作:自动扫描

在检测触摸屏操作,配置MAX1234,自动数字化触摸屏的接触位置时,写入寄存器0x40 (ADC控制),其PENSTS=1,ADSTS=0 (请参考MAX1233/MAX1234数据资料的表6)。第一次接触屏幕时,/PENIRQ信号暂时变为低电平,并在读取X寄存器之前不会变化。表13. 触摸屏检测命令序列:自动扫描

DEMO1234 Command |

Action | SPI data in |

Verification |

| Optional: connect oscilloscope to PENIRQ-bar | |||

I C 1 3 |

Configure PENIRQ-bar pulse accumulator: falling-edge trigger | ||

I 0 1 |

Reset the pulse accumulator | ||

I R 1 |

Read the number of times PENIRQ-bar has pulsed low | count = 0 | |

T W AC 8bff |

Wait for touch, then scan X,Y,Z1,Z2 | 0x0040 0x8bff |

|

| Touch the touch screen | PENIRQ pulse | ||

I R 1 |

Read the number of times PENIRQ-bar has pulsed low | count has increased | |

T R P |

Read X,Y,Z1,Z2 conversion results | 0x8000 0x0000 0x8001 0x0000 0x8002 0x0000 0x8003 0x0000 |

|

| Touch the touch screen | PENIRQ pulse | ||

I R 1 |

Read the number of times PENIRQ-bar has pulsed low | count has increased | |

T R P |

Read X,Y,Z1,Z2 conversion results | 0x8000 0x0000 0x8001 0x0000 0x8002 0x0000 0x8003 0x0000 |

|

| Touch the touch screen | PENIRQ pulse | ||

I R 1 |

Read the number of times PENIRQ-bar has pulsed low | count has increased | |

T R P |

Read X,Y,Z1,Z2 conversion results | 0x8000 0x0000 0x8001 0x0000 0x8002 0x0000 0x8003 0x0000 |

4) 键盘和通用输入/输出引脚

下面的例子介绍了怎样使用DEMO1234.EXE程序来扫描键盘,怎样使用GPIO键盘扫描引脚。4.1) 配置键盘和GPIO引脚

GPIO控制寄存器将每个C1–C4和R1–R4引脚分别配置为输入、输出或者是键盘的一部分(请参考MAX1233/MAX1234数据资料的表26和表27)。此外,写入GPIO上拉禁止寄存器,将输出引脚配置为开漏输出。表14. 键盘和GPIO配置实例

DEMO1234 Command |

Action | SPI data in |

T W GC FFFF |

Keypad: none; GPIO outputs: C4,C3,C2,C1,R4,R3,R2,R1; GPIO inputs: none |

0x004f 0xffff |

T W GC FF00 |

Keypad: none; GPIO outputs: none; GPIO inputs: C4,C3,C2,C1,R4,R3,R2,R1 |

0x004f 0xff00 |

T W GC 0000 |

Keypad: (C4,C3,C2,C1) x (R4,R3,R2,R1); GPIO outputs: none; GPIO inputs: none |

0x004f 0x0000 |

T W GC C8C0 |

Keypad: (C2,C1) x (R3,R2,R1); GPIO outputs: C4,C3; GPIO input: R4 |

0x004f 0xc8c0 |

T W GP 4000 |

GPIO pullup disable: C3 | 0x004e 0x4000 |

4.2) 读写GPIO引脚

GPIO数据寄存器读取GPIO输入引脚,写入GPIO输出引脚。注意:在这些例子中,C3、C4和R4是引脚名称,而不是元件名称。表15. GPIO实例

DEMO1234 Command |

Action | SPI data in |

Verification |

T W GC C8C0 |

Keypad: (C2,C1) x (R3,R2,R1); GPIO outputs: C4,C3; GPIO input: R4 |

0x004f 0xc8c0 |

|

T W GP 4000 |

GPIO pullup disable: C3 | 0x004e 0x4000 |

|

| Connect external resistor between C3 pin and DVDD | |||

| Connect DVM to C4 pin | |||

T W GD 8000 |

GPIO write C4 = 1 | 0x000f 0x8000 |

C4 pin = high |

T W GD 0000 |

GPIO write C4 = 0 | 0x000f 0x0000 |

C4 pin = low |

T W GD 8000 |

GPIO write C4 = 1 | 0x000f 0x8000 |

C4 pin = high |

T W GD 0000 |

GPIO write C4 = 0 | 0x000f 0x0000 |

C4 pin = low |

| Connect DVM to C3 pin | |||

T W GD 4000 |

GPIO write C3 = 1 | 0x000f 0x4000 |

C3 pin = high |

T W GD 0000 |

GPIO write C3 = 0 | 0x000f 0x0000 |

C3 pin = low |

T W GD 4000 |

GPIO write C3 = 1 | 0x000f 0x4000 |

C3 pin = high |

T W GD 0000 |

GPIO write C3 = 0 | 0x000f 0x0000 |

C3 pin = low |

| Connect R4 pin to DVDD | |||

T R GD |

GPIO read | 0x800f 0x0000 |

Buffer = 0x0800 |

| Connect R4 pin to GND | |||

T R GD |

GPIO read | 0x800f 0x0000 |

Buffer = 0x0000 |

4.3) 检测按键:自动扫描

可以配置键盘控制寄存器在探测到有按键按下时,自动扫描键盘。表16. 按键命令序列:自动扫描

DEMO1234 Command |

Action | SPI data in |

Verification |

| Optional: connect oscilloscope to KEYIRQ-bar | |||

I C 0 3 |

Configure KEYIRQ-bar pulse accumulator: falling-edge trigger | ||

I 0 0 |

Reset the pulse accumulator | ||

I R 0 |

Read the number of times KEYIRQ-bar has pulsed low | count = 0 | |

T W GC 0000 |

Keypad: (C4,C3,C2,C1) x (R4,R3,R2,R1); GPIO outputs: none; GPIO inputs: none |

0x004f 0x0000 |

|

T W KC bf00 |

Wait for keypress; maximum debounce and hold times |

0x0041 0xbf00 |

|

| Press and release R1C1 (key "1") | KEYIRQ pulse | ||

I R 0 |

Read the number of times KEYIRQ-bar has pulsed low | count has increased | |

T R KB |

Read raw keypad result | 0x8004 0x0000 |

0x0001 = R1C1 key |

| Press and release R2C2 (key "5") | KEYIRQ pulse | ||

I R 0 |

Read the number of times KEYIRQ-bar has pulsed low | count has increased | |

T R KB |

Read raw keypad result | 0x8004 0x0000 |

0x0020 = R2C2 key |

| Press and release R3C2 (key "8") | KEYIRQ pulse | ||

I R 0 |

Read the number of times KEYIRQ-bar has pulsed low | count has increased | |

T R KB |

Read raw keypad result | 0x8004 0x0000 |

0x0040 = R3C2 key |

4.4) 从键盘中屏蔽单个按键

使用键盘屏蔽寄存器和键盘2结果寄存器来屏蔽每个按键。屏蔽掉的按键被扫描至KPD寄存器,但是不在键盘2结果寄存器中报告。表17. 按键命令序列:屏蔽单个按键

DEMO1234 Command |

Action | SPI data in |

Verification |

T W GC 0000 |

Keypad: (C4,C3,C2,C1) x (R4,R3,R2,R1); GPIO outputs: none; GPIO inputs: none |

0x004f 0x0000 |

|

T W KC bf00 |

Wait for keypress; maximum debounce and hold times |

0x0041 0xbf00 |

|

T W KM 0020 |

Mask only R2C2 key | 0x0050 0x0020 |

|

| Press and release R1C1 (key "1") | |||

T R KB |

Read raw keypad result | 0x8004 0x0000 |

0x0001 = R1C1 key |

T R K2 |

Read masked keypad result | 0x8011 0x0000 |

0x0001 = R1C1 key |

| Press and release R2C2 (key "5") | |||

T R KB |

Read raw keypad result | 0x8004 0x0000 |

0x0020 = R2C2 key |

T R K2 |

Read masked keypad result | 0x8011 0x0000 |

0x0000 = no key |

| Press and release R3C2 (key "8") | |||

T R KB |

Read raw keypad result | 0x8004 0x0000 |

0x0040 = R3C2 key |

T R K2 |

Read masked keypad result | 0x8011 0x0000 |

0x0040 = R3C2 key |

4.5) 从键盘中屏蔽一列

使用键盘列寄存器来屏蔽所有列。不扫描屏蔽列,因此,KPD寄存器不会探测这些列中的按键。表18. 按键命令序列:屏蔽键盘的一列

DEMO1234 Command |

Action | SPI data in |

Verification |

T W GC 0000 |

Keypad: (C4,C3,C2,C1) x (R4,R3,R2,R1); GPIO outputs: none; GPIO inputs: none |

0x004f 0x0000 |

|

T W KC bf00 |

Wait for keypress; maximum debounce and hold times |

0x0041 0xbf00 |

|

T W KK 2000 |

Mask entire C2 column | 0x0051 0x2000 |

|

| Press and release R1C1 (key "1") | |||

T R KB |

Read raw keypad result | 0x8004 0x0000 |

0x0001 = R1C1 key |

| Press and release R2C2 (key "5") | |||

T R KB |

Read raw keypad result | 0x8004 0x0000 |

(previous value) |

| Press and release R3C2 (key "8") | |||

T R KB |

Read raw keypad result | 0x8004 0x0000 |

(previous value) |

| Press and release R2C3 (key "6") | |||

T R KB |

Read raw keypad result | 0x8004 0x0000 |

0x0200 = R2C3 key |

5)电源管理

表19. 关断命令DEMO1234 Command |

Action | SPI data in |

Verification |

T W AC C000 |

Power off ADC | 0x0040 0xc000 |

— |

T W AC 0300 |

Power off internal reference | 0x0040 0x0300 |

REF = not driven |

T W DC 8000 |

Disable DAC | 0x0042 0x8000 |

DACOUT = 0.0V |

T W KC C000 |

Power off keypad | 0x0041 0xc000 |

— |

6) 菜单系统

全部源代码实现下面的控制台菜单系统,它连接至MINIQUSB+模块。CmodComm测试程序主菜单—在连接前

A) adjust timing parameters

L) CmodLog... functions

C) connect

D) Debug Messages

X) exit

对C (连接)命令的响应

C

Hardware supports optimized native SMBus commands.

Board connected.

Got board banner: Maxim MINIQUSB V01.05.41 >

Firmware version is OK.

(configured for SPI auto-CS 4-byte mode) (SCLK=2MHz) ...

主菜单—连接后有效

T) Test the device

8) CmodP8Bus... functions

A) adjust timing parameters

L) CmodLog... functions

P) CmodPin... functions

S) CmodSpi... functions

M) CmodSMBus... functions

$) CmodCommStringWrite list of hex codes

R) CmodBoardReset

D) Disconnect

测试菜单命令—连接后有效

R) Read register

W) Write register

M0) measure no measurement; configure reference

M1) measure X,Y

M2) measure X,Y,Z1,Z2

M3) measure X

M4) measure Y

M5) measure Z1,Z2

M6) measure BAT1/4

M7) measure BAT2/4

M8) measure AUX1

M9) measure AUX2

MA) measure TEMP1

MB) measure BAT1/4,BAT2/4,AUX1,AUX2,TEMP1,TEMP2

MC) measure TEMP1,TEMP2

MD) no measurement; drive Y+,Y-

ME) no measurement; drive X+,X-

MF) no measurement; drive Y+,X-

.) Exit this menu

6.1) 寄存器读/写命令

表20. 读取寄存器助记符DEMO1234 Command |

Mnemonic | SPI data in |

T R A1 |

Test Read AUX1 register | 0x8007 0x0000 |

T R A2 |

Test Read AUX2 register | 0x8008 0x0000 |

T R AC |

Test Read ADC_control register | 0x8040 0x0000 |

T R AX |

Test Read X register | 0x8000 0x0000 |

T R AY |

Test Read Y register | 0x8001 0x0000 |

T R AZ1 |

Test Read Z1 register | 0x8002 0x0000 |

T R AZ2 |

Test Read Z2 register | 0x8003 0x0000 |

T R B1 |

Test Read BAT1 register | 0x8005 0x0000 |

T R B2 |

Test Read BAT2 register | 0x8006 0x0000 |

T R DC |

Test Read DAC_control register | 0x8042 0x0000 |

T R DD |

Test Read DAC_data register | 0x800b 0x0000 |

T R GC |

Test Read GPIO_control register | 0x804f 0x0000 |

T R GD |

Test Read GPIO_data register | 0x800f 0x0000 |

T R GP |

Test Read GPIO_pullup register | 0x804e 0x0000 |

T R K1 |

Test Read KPDATA1 register | 0x8010 0x0000 |

T R K2 |

Test Read KPDATA2 register | 0x8011 0x0000 |

T R KB |

Test Read KPD register | 0x8004 0x0000 |

T R KC |

Test Read KEY_control register | 0x8041 0x0000 |

T R KK |

Test Read KPCOLMASK register | 0x8051 0x0000 |

T R KM |

Test Read KPKEYMASK register | 0x8050 0x0000 |

T R T1 |

Test Read TEMP1 register | 0x8009 0x0000 |

T R T2 |

Test Read TEMP2 register | 0x800a 0x0000 |

表21. 写入寄存器助记符

DEMO1234 Command |

Mnemonic | SPI data in |

T W AC hexValue |

Test Write ADC_control register | 0x0040 hexValue |

T W DC hexValue |

Test Write DAC_control register | 0x0042 hexValue |

T W DD hexValue |

Test Write DAC_data register | 0x000b hexValue |

T W GC hexValue |

Test Write GPIO_control register | 0x004f hexValue |

T W GD hexValue |

Test Write GPIO_data register | 0x000f hexValue |

T W GP hexValue |

Test Write GPIO_pullup register | 0x004e hexValue |

T W KC hexValue |

Test Write KEY_control register | 0x0041 hexValue |

T W KK hexValue |

Test Write KPCOLMASK register | 0x0051 hexValue |

T W KM hexValue |

Test Write KPKEYMASK register | 0x0050 hexValue |

表22. 触摸屏测量命令序列

DEMO1234 Command |

Action (Triggered by A/D3210 Bits) | SPI data in Sequence |

T M1 |

Measure X,Y | 0x0040 0x07010x8000 0x00000x8001 0x0000 |

T M2 |

Measure X,Y,Z1,Z2 | 0x0040 0x0b010x8000 0x00000x8001 0x00000x8002 0x00000x8003 0x0000 |

T M3 |

Measure X | 0x0040 0x0f010x8000 0x0000 |

T M4 |

Measure Y | 0x0040 0x13010x8001 0x0000 |

T M5 |

Measure Z1,Z2 | 0x0040 0x17010x8002 0x00000x8003 0x0000 |

T MD |

No measurement; drive Y+,Y- | 0x0040 0x3701 |

T ME |

No measurement; drive X+,X- | 0x0040 0x3b01 |

T MF |

No measurement; drive Y+,X- | 0x0040 0x3f01 |

6.2) 中断和状态引脚命令

表23. 引脚状态读取命令DEMO1234 Command |

Action | SPI data in |

P R 5 |

Read KEYIRQ-bar pin status | N/A |

I C 0 3 |

Enable KEYIRQ-bar falling-edge trigger pulse accumulator | N/A |

I C 0 1 |

Enable KEYIRQ-bar rising-edge trigger pulse accumulator | N/A |

I C 0 0 |

Disable KEYIRQ-bar pulse accumulator | N/A |

I R 0 |

Read the number of times KEYIRQ-bar has pulsed low | N/A |

I 0 0 |

Clear the KEYIRQ-bar pulse accumulator | N/A |

P R 6 |

Read PENIRQ-bar pin status | N/A |

I C 1 3 |

Enable PENIRQ-bar falling-edge trigger pulse accumulator | N/A |

I C 1 1 |

Enable PENIRQ-bar rising-edge trigger pulse accumulator | N/A |

I C 1 0 |

Disable PENIRQ-bar pulse accumulator | N/A |

I R 1 |

Read the number of times PENIRQ-bar has pulsed low | N/A |

I 0 1 |

Clear the PENIRQ-bar pulse accumulator | N/A |

P R 7 |

Read BUSY-bar pin status | N/A |

6.3) 加入到更新后的MINIQUSB+固件中的命令

表24. 更新后MINIQUSB+固件01.05.40支持的SPI命令DEMO1234 Command |

Action | CPOL | CPHA | CS-Bar Control | AF Length |

S C L0 |

Configure SPI for CPOL=0 | 0 | — | GPIO-K9 | 1 byte |

S C L1 |

Configure SPI for CPOL=1 | 1 | — | GPIO-K9 | 1 byte |

S C A0 |

Configure SPI for CPHA=0 | — | 0 | GPIO-K9 | 1 byte |

S C A1 |

Configure SPI for CPHA=1 | — | 1 | GPIO-K9 | 1 byte |

S C C0 |

Configure SPI for 8-bit | — | — | GPIO-K9 | 1 byte |

S C C1 |

Configure SPI for 8-bit auto-CS-bar | — | — | Automatic | 1 byte |

S C C2 |

Configure SPI for 16-bit auto-CS-bar | — | — | Automatic | 2 bytes |

S C C3 |

Configure SPI for 24-bit auto-CS-bar | — | — | Automatic | 3 bytes |

S C C4 |

Configure SPI for 32-bit auto-CS-bar | — | — | Automatic | 4 bytes |

$ 2 AE 00 |

Configure SPI for 8-bit | 0 | 0 | GPIO-K9 | 1 byte |

$ 2 AE 01 |

Configure SPI for 8-bit | 0 | 1 | GPIO-K9 | 1 byte |

$ 2 AE 02 |

Configure SPI for 8-bit | 1 | 0 | GPIO-K9 | 1 byte |

$ 2 AE 03 |

Configure SPI for 8-bit | 1 | 1 | GPIO-K9 | 1 byte |

$ 2 AE 08 |

Configure SPI for 8-bit auto-CS-bar | 0 | 0 | Automatic | 1 byte |

$ 2 AE 09 |

Configure SPI for 8-bit auto-CS-bar | 0 | 1 | Automatic | 1 byte |

$ 2 AE 0A |

Configure SPI for 8-bit auto-CS-bar | 1 | 0 | Automatic | 1 byte |

$ 2 AE 0B |

Configure SPI for 8-bit auto-CS-bar | 1 | 1 | Automatic | 1 byte |

$ 2 AE 18 |

Configure SPI for 16-bit auto-CS-bar | 0 | 0 | Automatic | 2 bytes |

$ 2 AE 19 |

Configure SPI for 16-bit auto-CS-bar | 0 | 1 | Automatic | 2 bytes |

$ 2 AE 1A |

Configure SPI for 16-bit auto-CS-bar | 1 | 0 | Automatic | 2 bytes |

$ 2 AE 1B |

Configure SPI for 16-bit auto-CS-bar | 1 | 1 | Automatic | 2 bytes |

$ 2 AE 28 |

Configure SPI for 24-bit auto-CS-bar | 0 | 0 | Automatic | 3 bytes |

$ 2 AE 29 |

Configure SPI for 24-bit auto-CS-bar | 0 | 1 | Automatic | 3 bytes |

$ 2 AE 2A |

Configure SPI for 24-bit auto-CS-bar | 1 | 0 | Automatic | 3 bytes |

$ 2 AE 2B |

Configure SPI for 24-bit auto-CS-bar | 1 | 1 | Automatic | 3 bytes |

$ 2 AE 38 |

Configure SPI for 32-bit auto-CS-bar | 0 | 0 | Automatic | 4 bytes |

$ 2 AE 39 |

Configure SPI for 32-bit auto-CS-bar | 0 | 1 | Automatic | 4 bytes |

$ 2 AE 3A |

Configure SPI for 32-bit auto-CS-bar | 1 | 0 | Automatic | 4 bytes |

$ 2 AE 3B |

Configure SPI for 32-bit auto-CS-bar | 1 | 1 | Automatic | 4 bytes |

$ 2 AF xx |

Perform an 8-bit SPI transfer (CS-bar = GPIO or auto-CS-bar = 1-byte) | — | — | — | 1 byte |

$ 3 AF xx xx |

Perform a 16-bit SPI transfer (requires auto-CS-bar = 2-byte mode) | — | — | — | 2 bytes |

$ 4 AF xx xx xx |

Perform a 24-bit SPI transfer (requires auto-CS-bar = 3-byte mode) | — | — | — | 3 bytes |

$ 5 AF xx xx xx xx |

Perform a 32-bit SPI transfer (requires auto-CS-bar = 4-byte mode) | — | — | — | 4 bytes |

$ 2 F9 0 |

Drive CS-bar pin low | — | — | GPIO-K9 | — |

$ 2 F9 1 |

Drive CS-bar pin high | — | — | GPIO-K9 | — |

表25. 更新后MINIQUSB+固件01.05.41中的中断脉冲累加器命令

DEMO1234 Command |

Action | Int | GPIO Input | Firmware Command |

$ 2 C3 00 |

Query which of the C3 commands are supported; the return value is a 2-byte bitmap of commands C300 to C30F, msb first | — | — | C3 00 |

I Q 0 |

Query configuration of pulse accumulator | INT0 | GPIO-K5 | C3 01 00 |

I Q 1 |

Query configuration of pulse accumulator | INT1 | GPIO-K6 | C3 01 01 |

I Q 2 |

Query configuration of pulse accumulator | INT2 | GPIO-K7 | C3 01 02 |

I Q 3 |

Query configuration of pulse accumulator | INT3 | GPIO-K8 | C3 01 03 |

I C 0 0 |

Configure pulse accumulator: disable interrupt | INT0 | GPIO-K5 | C3 02 00 00 |

I C 1 0 |

Configure pulse accumulator: disable interrupt | INT1 | GPIO-K6 | C3 02 01 00 |

I C 2 0 |

Configure pulse accumulator: disable interrupt | INT2 | GPIO-K7 | C3 02 02 00 |

I C 3 0 |

Configure pulse accumulator: disable interrupt | INT3 | GPIO-K8 | C3 02 03 00 |

I C 0 1 |

Configure pulse accumulator: rising-edge trigger | INT0 | GPIO-K5 | C3 02 00 01 |

I C 1 1 |

Configure pulse accumulator: rising-edge trigger | INT1 | GPIO-K6 | C3 02 01 01 |

I C 2 1 |

Configure pulse accumulator: rising-edge trigger | INT2 | GPIO-K7 | C3 02 02 01 |

I C 3 1 |

Configure pulse accumulator: rising-edge trigger | INT3 | GPIO-K8 | C3 02 03 01 |

I C 0 3 |

Configure pulse accumulator: falling-edge trigger | INT0 | GPIO-K5 | C3 02 00 03 |

I C 1 3 |

Configure pulse accumulator: falling-edge trigger | INT1 | GPIO-K6 | C3 02 01 03 |

I C 2 3 |

Configure pulse accumulator: falling-edge trigger | INT2 | GPIO-K7 | C3 02 02 03 |

I C 3 3 |

Configure pulse accumulator: falling-edge trigger | INT3 | GPIO-K8 | C3 02 03 03 |

I R 0 |

Read pulse accumulator | INT0 | GPIO-K5 | C3 03 00 |

I R 1 |

Read pulse accumulator | INT1 | GPIO-K6 | C3 03 01 |

I R 2 |

Read pulse accumulator | INT2 | GPIO-K7 | C3 03 02 |

I R 3 |

Read pulse accumulator | INT3 | GPIO-K8 | C3 03 03 |

I 0 0 |

Clear pulse accumulator | INT0 | GPIO-K5 | C3 04 00 |

I 0 1 |

Clear pulse accumulator | INT1 | GPIO-K6 | C3 04 01 |

I 0 2 |

Clear pulse accumulator | INT2 | GPIO-K7 | C3 04 02 |

I 0 3 |

Clear pulse accumulator | INT3 | GPIO-K8 | C3 04 03 |

I S 0 xx |

Set pulse accumulator count xx = 0 to 255 | INT0 | GPIO-K5 | C3 05 00 xx |

I S 1 xx |

Set pulse accumulator count xx = 0 to 255 | INT1 | GPIO-K6 | C3 05 01 xx |

I S 2 xx |

Set pulse accumulator count xx = 0 to 255 | INT2 | GPIO-K7 | C3 05 02 xx |

I S 3 xx |

Set pulse accumulator count xx = 0 to 255 | INT3 | GPIO-K8 | C3 05 03 xx |

德赢Vwin官网 App

德赢Vwin官网 App

评论